Bioethanol process flow diagram

Home » Background » Bioethanol process flow diagramYour Bioethanol process flow diagram images are ready. Bioethanol process flow diagram are a topic that is being searched for and liked by netizens now. You can Get the Bioethanol process flow diagram files here. Find and Download all royalty-free photos and vectors.

If you’re searching for bioethanol process flow diagram images information connected with to the bioethanol process flow diagram topic, you have visit the right blog. Our site always provides you with hints for seeing the maximum quality video and image content, please kindly surf and find more informative video articles and images that match your interests.

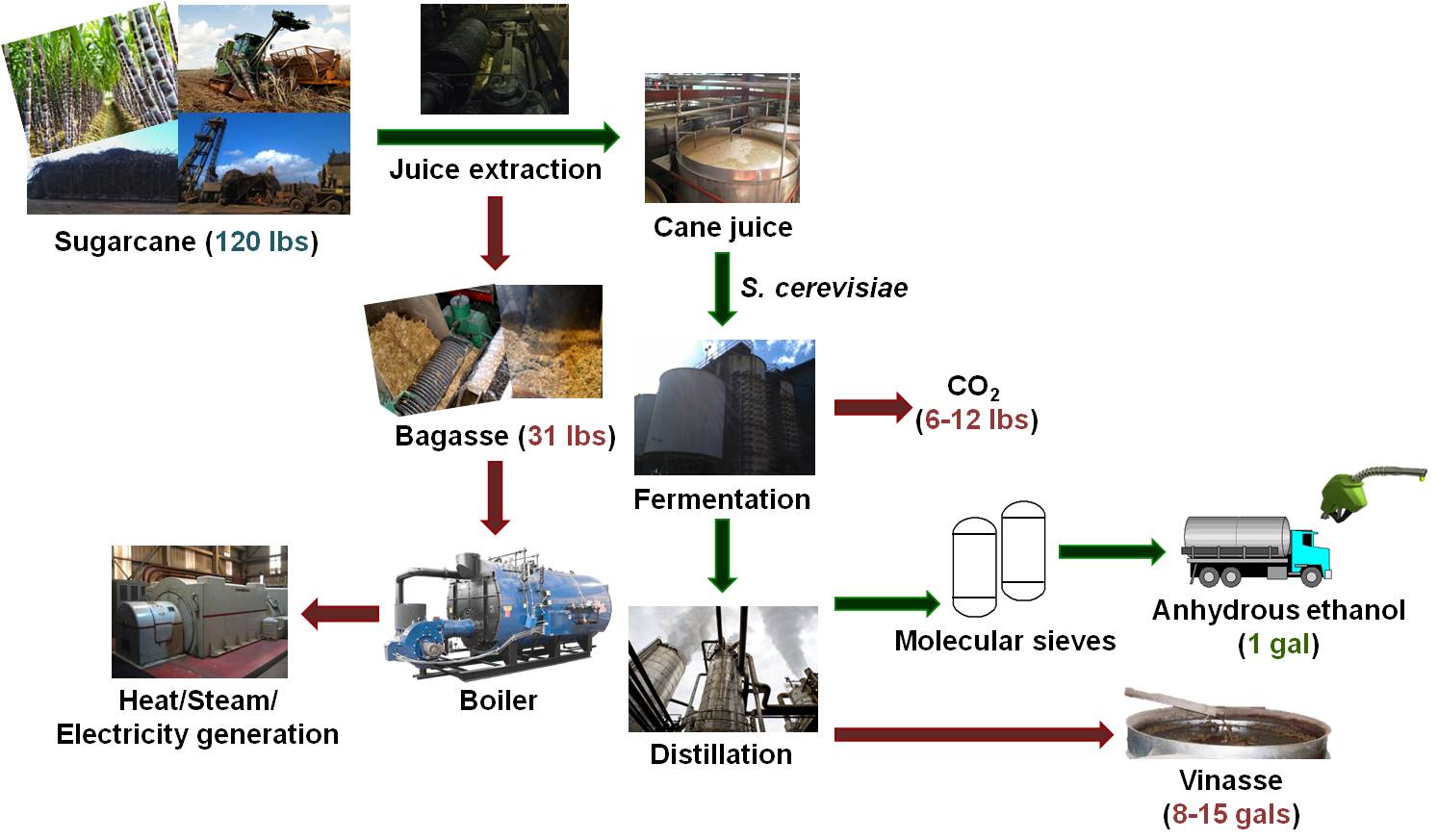

Bioethanol Process Flow Diagram. In the second stage bioethanol is reformed with steam to generate pure hydrogen following a thermochemical conversion process. Bioethanol Production Wet milling process corn kernel is soaked in warm water proteins broken down starch present in the corn is released thus softening the kernel for the milling process microorganisms fibre and starch products are produced. Introduction of ethanol properties of ethanol process flow diagram of production of ethanol from molasses. In the distillation process ethanol is produced.

Alcohol Industry Is One Of The Rapidly Booming Industries In This World With Each Year Consumption And Production Of Alcohol Both Are Increasing At A Dramatic From pinterest.com

Alcohol Industry Is One Of The Rapidly Booming Industries In This World With Each Year Consumption And Production Of Alcohol Both Are Increasing At A Dramatic From pinterest.com

In the distillation process ethanol is produced. 2 Block flow diagram of the conventional bioethanol production process from sugarcane. 1 ton of biomassday Enzyme tank Flash tank Cake tank Distillation column Centrate tank Recycle Solids Liquids Hydrolyzer 9000-L fermenters Belt. Brown algae exposed to seasonal changes usually accumulate mannitol and laminaran in the light. The flow sheet diagram is the process of bioetha nol plant in Biomass Laboratory the base study which is used to simulate and analyze in this research. Flow is diverted to second dry column then first column is regenerated Recovery 98 Purity 995 dehydration alcohol as standard.

Bioethanol is produced in the first stage according to a biochemical conversion pathway.

In the first section are reported the commercially available processes together with hints to. Introduction of ethanol properties of ethanol process flow diagram of production of ethanol from molasses. The flowsheet diagram of the integrated plant is shown in Fig. Bioethanol Production Wet milling process corn kernel is soaked in warm water proteins broken down starch present in the corn is released thus softening the kernel for the milling process microorganisms fibre and starch products are produced. 2 Process Flow Diagrams Refinery. The Arabs and Romans learned to isolate the alcohol and to.

Source: pinterest.com

Source: pinterest.com

Figure 31 Process Flow Diagram for Bioethanol Production from Cassava 31 Figure 32 Graph of Standard Calibration Curve for Glucose absorbance versus mgml 37 Figure 33 Graph of Standard Calibration Curve for Ethanol 39 Figure 34 Graph of Standard calibration of Cell Concentration mgml 40. Process flow diagram of bioethanol production from OPF juice 29. In the beginning the ethylene stream is cooled to 23 C. Bioethanol production during batch fermentation by S. Most efficient and simple solution for the process which consists of 4 stages.

Source: pinterest.com

Source: pinterest.com

Feedstock information was supplied by Outokumpu whereas process variables and equipment. Process flow diagram of Production of ethanol from molasses - YouTube. Gas pretreatment bacterial growth fermentation and product separation. Cerevisiae Bakers yeast in fresh OPF juice fresh sugarcane juice and control medium. 2 Flow diagram of basic configuration of process 2 Steam is used as a heating medium in heat exchangers HE-1 to increase the material after sterilization.

Source: pinterest.com

Source: pinterest.com

Feedstock information was supplied by Outokumpu whereas process variables and equipment. The first stage is to heat up the feed stream by adding steam and H 2 SO 4 for thermal acid hydrolysis. Process most ethanol production industries use the batch mode Tomas-Pejo et al 2008. Brown algae exposed to seasonal changes usually accumulate mannitol and laminaran in the light. The fermented broth is centrifuged after.

Source: pinterest.com

Source: pinterest.com

PROCESS FLOW DIAGRAM OF ETHANOL PRODUCTION - YouTube. Due to high demand the project proposes a process design of 10000 metric tons bioethanol per year using fed-batch fermentation process with Saccharomyces cerevisiae CBS 8066 as. Three Basic Refinery Process Flows SEPARATIONCONVERSION STORAGE AND BLENDING Crude Gasoline Gas Naphtha Kerosene Fuel Oil ResidualAsphalt Separation Crude Oil into Various Fractions Based on Boiling Point Crude Desalter Atmosphere Crude Unit Vacuum Crude Unit. Introduction of ethanol properties of ethanol process flow diagram of production of ethanol from molasses. A simplified process flow diagram for et hanol production.

Source: pinterest.com

Source: pinterest.com

Due to high demand the project proposes a process design of 10000 metric tons bioethanol per year using fed-batch fermentation process with Saccharomyces cerevisiae CBS 8066 as. Process Flow Diagram of the Process Development Unit Centrifuge Ethanol storage Condenser Washer Debris Water Feedstock Mill Cyclone Feed hopper Plug feeder Steam Acid Water Seed fermenters Nutrient tank Capacity. Gas pretreatment bacterial growth fermentation and product separation. Bioethanol Production Wet milling process corn kernel is soaked in warm water proteins broken down starch present in the corn is released thus softening the kernel for the milling process microorganisms fibre and starch products are produced. In a subsequent chemical treatment phosphoric acid is added to sugarcane juice to increase juice phosphates content and enhance impurities removal during settlement followed by the first heating oper-.

Source: pinterest.com

Source: pinterest.com

In the beginning the ethylene stream is cooled to 23 C. Bioethanol Process Flow v2 - Free download as Powerpoint Presentation ppt pptx PDF File pdf Text File txt or view presentation slides online. The flow sheet diagram is the process of bioetha nol plant in Biomass Laboratory the base study which is used to simulate and analyze in this research. In the second stage bioethanol is reformed with steam to generate pure hydrogen following a thermochemical conversion process. Fermentation process is carried out in two or three fomenters with addition of yeast at concentration 10 gL.

Source: pinterest.com

Source: pinterest.com

In the distillation process ethanol is produced. Three Basic Refinery Process Flows SEPARATIONCONVERSION STORAGE AND BLENDING Crude Gasoline Gas Naphtha Kerosene Fuel Oil ResidualAsphalt Separation Crude Oil into Various Fractions Based on Boiling Point Crude Desalter Atmosphere Crude Unit Vacuum Crude Unit. Ethanol derived from agricultural sources as distinct from petrochemical sources Originally it was produced by the spontaneous fermentation of sugars and was consumed by ancient races for its intoxicating effects. In the first section are reported the commercially available processes together with hints to. PROCESS FLOW DIAGRAM OF ETHANOL PRODUCTION - YouTube.

Source: pinterest.com

Source: pinterest.com

In the beginning the ethylene stream is cooled to 23 C. Schematic process flow diagram of base cases bioethanol production from waste papers using Cellic Ctec 1 dashed boxes indicate the detailed unit processes 18. Bioethanol Production Wet milling process corn kernel is soaked in warm water proteins broken down starch present in the corn is released thus softening the kernel for the milling process microorganisms fibre and starch products are produced. The process flow diagram below shows the basic steps in production of ethanol from cellulosic biomass. Process flow diagram of bioethanol production from OPF juice 29.

Source: pinterest.com

Source: pinterest.com

Introduction of ethanol properties of ethanol process flow diagram of production of ethanol from molasses. 37 g Of nutrients containing 90 of sodium 32 bar for 3 h 26. The process flow diagram below shows the basic steps in production of ethanol from cellulosic biomass. Bioethanol Process Flow v2 - Free download as Powerpoint Presentation ppt pptx PDF File pdf Text File txt or view presentation slides online. In the distillation process ethanol is produced.

Source: pinterest.com

Source: pinterest.com

Then it passes through an expansion valve which reduces the temperature further to 28. The fermented broth is centrifuged after. Bioethanol is produced in the first stage according to a biochemical conversion pathway. The first stage is to heat up the feed stream by adding steam and H 2 SO 4 for thermal acid hydrolysis. Process flow diagram of Production of ethanol from molasses - YouTube.

Source: pinterest.com

Source: pinterest.com

In the beginning the ethylene stream is cooled to 23 C. Process Flow Diagram of the Process Development Unit Centrifuge Ethanol storage Condenser Washer Debris Water Feedstock Mill Cyclone Feed hopper Plug feeder Steam Acid Water Seed fermenters Nutrient tank Capacity. Flow is diverted to second dry column then first column is regenerated Recovery 98 Purity 995 dehydration alcohol as standard. PROCESS FLOW DIAGRAM OF ETHANOL PRODUCTION - YouTube. The flow sheet diagram is the process of bioetha nol plant in Biomass Laboratory the base study which is used to simulate and analyze in this research.

Source: in.pinterest.com

Source: in.pinterest.com

Bioethanol production during batch fermentation by S. Due to high demand the project proposes a process design of 10000 metric tons bioethanol per year using fed-batch fermentation process with Saccharomyces cerevisiae CBS 8066 as. A simplified process flow diagram for bioethanol production plant A pretreatment section carried out in two stages. Process flow diagram of Production of ethanol from molasses - YouTube. A simplified process flow diagram for et hanol production.

Source: pinterest.com

Source: pinterest.com

Bioethanol production during batch fermentation by S. 37 g Of nutrients containing 90 of sodium 32 bar for 3 h 26. Bioethanol is produced in the first stage according to a biochemical conversion pathway. A simplified process flow diagram for bioethanol production plant A pretreatment section carried out in two stages. The flow sheet diagram is the process of bioetha nol plant in Biomass Laboratory the base study which is used to simulate and analyze in this research.

Source: pinterest.com

Source: pinterest.com

This State of the Art deals with the ethanol production from current processes based on the use of sugar and starch as feedstock and those under development based on lignocellulosic biomass. 2 Flow diagram of basic configuration of process 2 Steam is used as a heating medium in heat exchangers HE-1 to increase the material after sterilization. The first stage is to heat up the feed stream by adding steam and H 2 SO 4 for thermal acid hydrolysis. The fermented broth is centrifuged after. Process most ethanol production industries use the batch mode Tomas-Pejo et al 2008.

Source: pinterest.com

Source: pinterest.com

Bioethanol is produced in the first stage according to a biochemical conversion pathway. A simplified process flow diagram for et hanol production. Then it passes through an expansion valve which reduces the temperature further to 28. Process flow diagram of Production of ethanol from molasses - YouTube. A simplified process flow diagram for bioethanol production plant A pretreatment section carried out in two stages.

Source: in.pinterest.com

Source: in.pinterest.com

In the second stage bioethanol is reformed with steam to generate pure hydrogen following a thermochemical conversion process. 1 ton of biomassday Enzyme tank Flash tank Cake tank Distillation column Centrate tank Recycle Solids Liquids Hydrolyzer 9000-L fermenters Belt. Bioethanol Production Wet milling process corn kernel is soaked in warm water proteins broken down starch present in the corn is released thus softening the kernel for the milling process microorganisms fibre and starch products are produced. Bioethanol Process Flow v2 - Free download as Powerpoint Presentation ppt pptx PDF File pdf Text File txt or view presentation slides online. Introduction of ethanol properties of ethanol process flow diagram of production of ethanol from molasses.

Source: pinterest.com

Source: pinterest.com

Gas pretreatment bacterial growth fermentation and product separation. In the distillation process ethanol is produced. 2 Flow diagram of basic configuration of process 2 Steam is used as a heating medium in heat exchangers HE-1 to increase the material after sterilization. In a subsequent chemical treatment phosphoric acid is added to sugarcane juice to increase juice phosphates content and enhance impurities removal during settlement followed by the first heating oper-. Note that there are a variety of options for pretreatment and other steps in the process and that several technologies combine two or all three of the hydrolysis and fermentation steps within the shaded box.

Source: in.pinterest.com

Source: in.pinterest.com

Brown algae exposed to seasonal changes usually accumulate mannitol and laminaran in the light. Due to high demand the project proposes a process design of 10000 metric tons bioethanol per year using fed-batch fermentation process with Saccharomyces cerevisiae CBS 8066 as. The process flow diagram below shows the basic steps in production of ethanol from cellulosic biomass. In a subsequent chemical treatment phosphoric acid is added to sugarcane juice to increase juice phosphates content and enhance impurities removal during settlement followed by the first heating oper-. 1 ton of biomassday Enzyme tank Flash tank Cake tank Distillation column Centrate tank Recycle Solids Liquids Hydrolyzer 9000-L fermenters Belt.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site good, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title bioethanol process flow diagram by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.