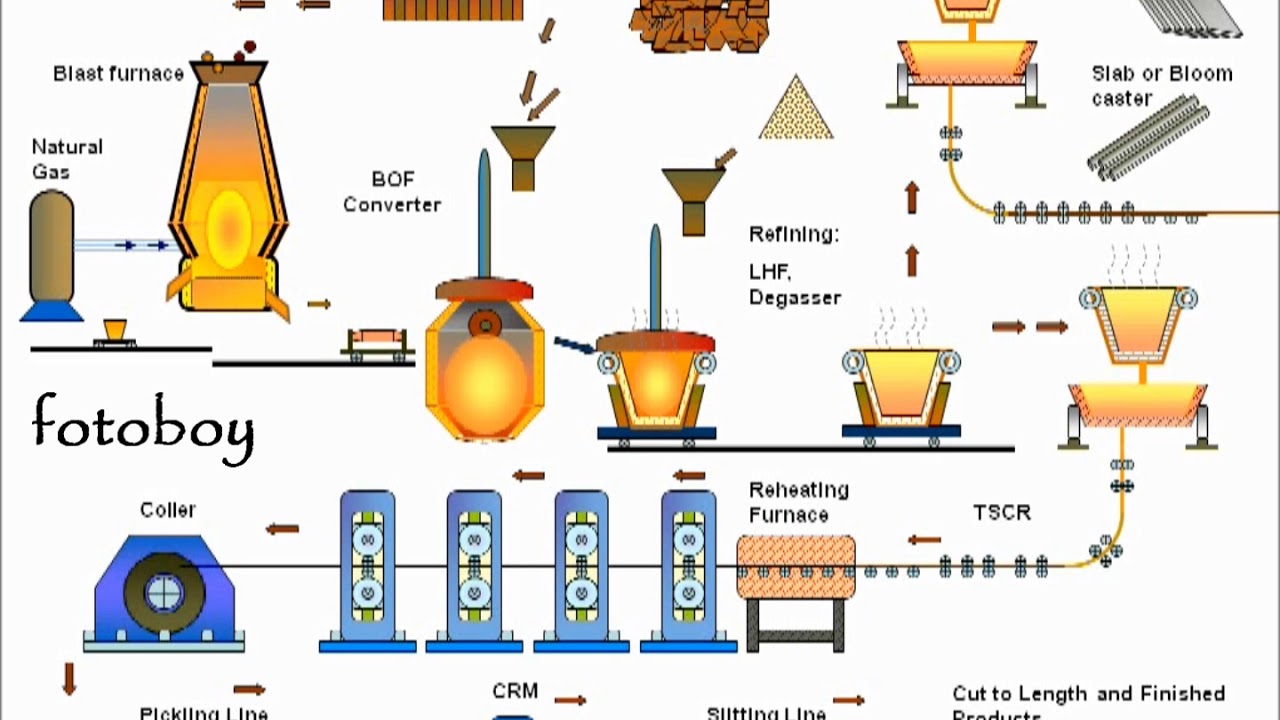

Blast furnace process flow diagram

Home » Background » Blast furnace process flow diagramYour Blast furnace process flow diagram images are available in this site. Blast furnace process flow diagram are a topic that is being searched for and liked by netizens now. You can Find and Download the Blast furnace process flow diagram files here. Download all royalty-free photos and vectors.

If you’re looking for blast furnace process flow diagram images information connected with to the blast furnace process flow diagram keyword, you have visit the ideal blog. Our website always provides you with hints for seeking the highest quality video and picture content, please kindly surf and find more informative video articles and images that fit your interests.

Blast Furnace Process Flow Diagram. Blast furnaces are used continuously and are only shut down when their brick lining needs replacing. 18 hours to produce blast furnace coke and 25 to 30 hours to produce foundry coke. Example of a Rist operating diagram 2. Unknown 21 August 2018 at 1214.

Blast Furnace Process An Overview Sciencedirect Topics From sciencedirect.com

Blast Furnace Process An Overview Sciencedirect Topics From sciencedirect.com

The task of the main sub topology layer is the depiction of the material flows of the blast furnace process. SEO Expert 21 November 2018 at 2147. Blast furnace process flow chart adhunik group of blast furnace process flow chart adhunik group of industries steel plant process flow with 36 files the blast furnace iron production molten iron ore is tapped at the bottom of the blast furnace poured into the iron ladle and removed for use the slag is removed at the tap hole although generally regarded as waste it is used in road making iron ore processing for the blast furnace blast furnace process. 2 Cohesive Zone Fig. Overview of blast furnace The blast furnace is the most popular iron making process. Blast Furnace and Process Description 3D Model.

June 25th 2018 - steel Sankey Diagrams The final raw material in the ironmaking process in line blast furnace operators to carefully control gas flow and chemical reactionsFlow Diagram Wikimedia Commons June 18th 2018 - A Flow Diagram Is A Diagram Representing Some Kind Of Flow Blast Furnace Sankey Diagram Are A Specific Type Of Flow Diagram.

Blast furnace operation-flow diagram Posted by Blast Furnace operation at 0132. The BF is a counter-current heat exchanger where hot gas ascends in the furnace giving heat to the descending raw material while reducing iron oxides. Blast furnaces are used to produce pig iron from iron ore for subsequent. The vessel is internally lined with cooling elements and refractory bricks and blocks. Share to Twitter Share to Facebook Share to Pinterest. Most Iron is taken s traight from the Blast F urnace to the.

Source: technologystudent.com

Source: technologystudent.com

The Slag is also tapped off at regular intervals. Blast furnace gas is the byproduct of casting steel production process in the steel industry and usually is composed of 22-25 CO 16-20 CO 2 4-5 H 2 and 51-55 of N 2 by volume. Unknown 21 August 2018 at 1214. A blast furnace is a special type of cylindrical furnace which is basically used for the purpose of smelting. Blast furnaces are used to produce pig iron from iron ore for subsequent.

Source: researchgate.net

Source: researchgate.net

A simplified diagram of a Blast Furnace is drawn below. Blast Furnace and Process Description 3D Model. The hearth zone is the bottom-most region where the hot metal and slag are stored. A typical blast furnace may be up to 32 metres in height and 10 metres in diameter. To generate the necessary heat and the reducing carbon monoxide gas CO the coke is burnt in the lower part of the blast furnace with the supply of the hot-blast.

Source: researchgate.net

Source: researchgate.net

The Slag is also tapped off at regular intervals. 3 General Schematic of Blast furnace internal zones Fig. June 25th 2018 - steel Sankey Diagrams The final raw material in the ironmaking process in line blast furnace operators to carefully control gas flow and chemical reactionsFlow Diagram Wikimedia Commons June 18th 2018 - A Flow Diagram Is A Diagram Representing Some Kind Of Flow Blast Furnace Sankey Diagram Are A Specific Type Of Flow Diagram. In order to operate a blast furnace stably and economically it is important to form an inverse-V shaped cohesive zone in the high Ore Coke Cohesive zone Central gas Improvement of liquid permeability in deadman Formation of cohesive zone as inverse V shape Deadman Deadman. So the industrial metals can be extracted from their ores like iron pig iron or copper.

Source: blastfurnaceoperationbyubay.blogspot.com

Source: blastfurnaceoperationbyubay.blogspot.com

Figure 2 a shows a schematic diagram of blast furnace interior. 1 A Schematic diagram of Blast furnace process Fig. Figure 1 flow diagram showing all the iron making processes. Blast furnace gas is the byproduct of casting steel production process in the steel industry and usually is composed of 22-25 CO 16-20 CO 2 4-5 H 2 and 51-55 of N 2 by volume. As the Furnace fills the molten Iron is T apped off.

Because of CO and H 2 are combustible blast furnace gas is the most significant energy source. The task of the main sub topology layer is the depiction of the material flows of the blast furnace process. These factors interact to determine the flow and distribution of. 12514 Steelmaking Process Basic Oxygen Furnaces - In the basic oxygen process BOP molten iron from a blast furnace and iron scrap are refined in a furnace by lancing or injecting high-purity oxygen. The individual chemical processes in the blast furnace are described in more detail in the following sections.

Source: researchgate.net

Source: researchgate.net

As the Furnace fills the molten Iron is T apped off. Unknown 21 August 2018 at 1214. They have thick steel sides lined with refractory bricks to ensure that heat is not lost. 12514 Steelmaking Process Basic Oxygen Furnaces - In the basic oxygen process BOP molten iron from a blast furnace and iron scrap are refined in a furnace by lancing or injecting high-purity oxygen. Blast furnace a vertical shaft furnace that produces liquid metals by the reaction of a flow of and they are also employed in processing lead copper and other metals.

Source: sinfo-t.jp

Source: sinfo-t.jp

The oxygen of the blast burns coke to CO and several combustion zones one in front of each tuyere exist in the tuyere zone. Blast furnace operation-flow diagram Posted by Blast Furnace operation at 0132. June 25th 2018 - steel Sankey Diagrams The final raw material in the ironmaking process in line blast furnace operators to carefully control gas flow and chemical reactionsFlow Diagram Wikimedia Commons June 18th 2018 - A Flow Diagram Is A Diagram Representing Some Kind Of Flow Blast Furnace Sankey Diagram Are A Specific Type Of Flow Diagram. So the industrial metals can be extracted from their ores like iron pig iron or copper. A blast furnace is a special type of cylindrical furnace which is basically used for the purpose of smelting.

Source: researchgate.net

Source: researchgate.net

Blast Furnace and Process Description 3D Model. SEO Expert 21 November 2018 at 2147. Overview of blast furnace The blast furnace is the most popular iron making process. The preheated air 10001300 C is blown through it. The BF is a counter-current heat exchanger where hot gas ascends in the furnace giving heat to the descending raw material while reducing iron oxides.

Source: researchgate.net

Source: researchgate.net

Blast furnace operation-flow diagram Posted by Blast Furnace operation at 0132. A simplified diagram of a Blast Furnace is drawn below. Share to Twitter Share to Facebook Share to Pinterest. The task of the main sub topology layer is the depiction of the material flows of the blast furnace process. The Slag is also tapped off at regular intervals.

Source: researchgate.net

Source: researchgate.net

To generate the necessary heat and the reducing carbon monoxide gas CO the coke is burnt in the lower part of the blast furnace with the supply of the hot-blast. The individual chemical processes in the blast furnace are described in more detail in the following sections. The BF is a counter-current heat exchanger where hot gas ascends in the furnace giving heat to the descending raw material while reducing iron oxides. Blast furnace a vertical shaft furnace that produces liquid metals by the reaction of a flow of air introduced under pressure into the bottom of the furnace with a mixture of metallic ore coke and flux fed into the top. In recent years the use of blast furnace gas is too high 1Foundries can use the produced gasses in.

Source: csc.com.tw

Source: csc.com.tw

In recent years the use of blast furnace gas is too high 1Foundries can use the produced gasses in. The word blast gives the idea of combustion air which is forcefully supplied or produced to the atmospheric pressure above. The carbon C contained in the coke initially reacts with the atmospheric oxygen in the hot-blast. When demand for coke is low coking times can be extended to 24 hours for blast furnace coke and to 48 hours for foundry coke. Blast furnace a vertical shaft furnace that produces liquid metals by the reaction of a flow of air introduced under pressure into the bottom of the furnace with a mixture of metallic ore coke and flux fed into the top.

Source: researchgate.net

Source: researchgate.net

The word blast gives the idea of combustion air which is forcefully supplied or produced to the atmospheric pressure above. The vessel is internally lined with cooling elements and refractory bricks and blocks. The individual chemical processes in the blast furnace are described in more detail in the following sections. 4 - Schematic diagram of blast furnace slag production and blast furnace operation Fig. Share to Twitter Share to Facebook Share to Pinterest.

Source: youtube.com

Source: youtube.com

The word blast gives the idea of combustion air which is forcefully supplied or produced to the atmospheric pressure above. 1 A Schematic diagram of Blast furnace process Fig. These factors interact to determine the flow and distribution of. Unknown 21 August 2018 at 1214. Figure 2 a shows a schematic diagram of blast furnace interior.

Source: britannica.com

Source: britannica.com

The task of the main sub topology layer is the depiction of the material flows of the blast furnace process. To generate the necessary heat and the reducing carbon monoxide gas CO the coke is burnt in the lower part of the blast furnace with the supply of the hot-blast. The word blast gives the idea of combustion air which is forcefully supplied or produced to the atmospheric pressure above. 1 A Schematic diagram of Blast furnace process Fig. The task of the main sub topology layer is the depiction of the material flows of the blast furnace process.

Source: sciencedirect.com

Source: sciencedirect.com

Modelling The blast furnace model consists of three distinct sub topologies or calculation layers. 18 hours to produce blast furnace coke and 25 to 30 hours to produce foundry coke. Modelling The blast furnace model consists of three distinct sub topologies or calculation layers. 4 - Schematic diagram of blast furnace slag production and blast furnace operation Fig. The Slag is also tapped off at regular intervals.

Source: researchgate.net

Source: researchgate.net

The preheated air 10001300 C is blown through it. When demand for coke is low coking times can be extended to 24 hours for blast furnace coke and to 48 hours for foundry coke. These factors interact to determine the flow and distribution of. Overview of blast furnace The blast furnace is the most popular iron making process. The hearth zone is the bottom-most region where the hot metal and slag are stored.

Source: researchgate.net

Source: researchgate.net

The BF is a counter-current heat exchanger where hot gas ascends in the furnace giving heat to the descending raw material while reducing iron oxides. Share to Twitter Share to Facebook Share to Pinterest. The word blast gives the idea of combustion air which is forcefully supplied or produced to the atmospheric pressure above. The input material is typically 70 percent molten metal and 30 percent scrap metal. Blast furnaces are used to produce pig iron from iron ore for subsequent.

Source: researchgate.net

Source: researchgate.net

Blast furnaces are used continuously and are only shut down when their brick lining needs replacing. 3 General Schematic of Blast furnace internal zones Fig. 12514 Steelmaking Process Basic Oxygen Furnaces - In the basic oxygen process BOP molten iron from a blast furnace and iron scrap are refined in a furnace by lancing or injecting high-purity oxygen. Blast furnaces are used continuously and are only shut down when their brick lining needs replacing. Example of a Rist operating diagram 2.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site beneficial, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title blast furnace process flow diagram by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.