Crude oil heater treater diagram

Home » Wallpapers » Crude oil heater treater diagramYour Crude oil heater treater diagram images are ready in this website. Crude oil heater treater diagram are a topic that is being searched for and liked by netizens now. You can Get the Crude oil heater treater diagram files here. Find and Download all royalty-free photos.

If you’re searching for crude oil heater treater diagram images information connected with to the crude oil heater treater diagram keyword, you have visit the ideal site. Our website frequently gives you suggestions for seeking the maximum quality video and image content, please kindly search and find more enlightening video content and graphics that match your interests.

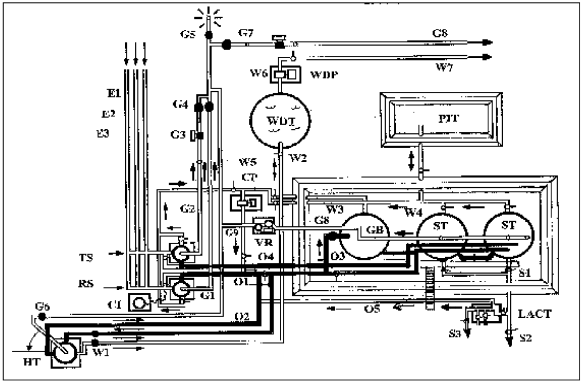

Crude Oil Heater Treater Diagram. The Horizontal Treater is designed to efficiently treat large capacities of crude oil by removing water and emulsion from the wellstream preparing the treated oil. Emersons heater treater solutions provide greater insight into treater health and process integrity resulting in fewer production allocation errors more effective maintenance and reduction in HSE risks. Keep it as a reference for. Figure 9 illustrates a typical vertical high pressure or low pressure oil-gas separator with pneumatic controls.

Figure 2 Failure Analysis Of Fire Tube Sleeve Of Heater Treater Springerlink From link.springer.com

Figure 2 Failure Analysis Of Fire Tube Sleeve Of Heater Treater Springerlink From link.springer.com

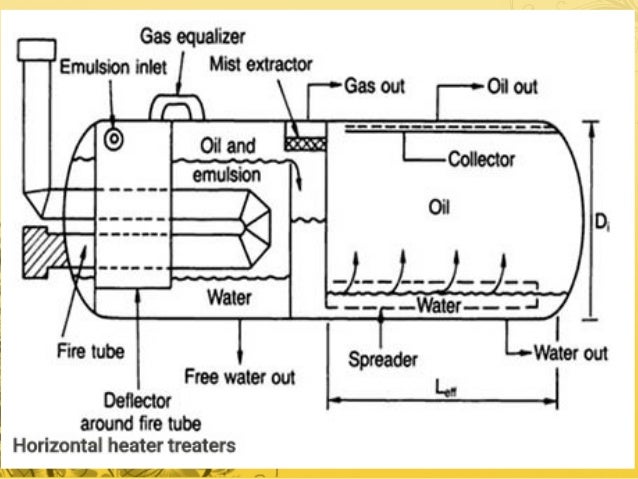

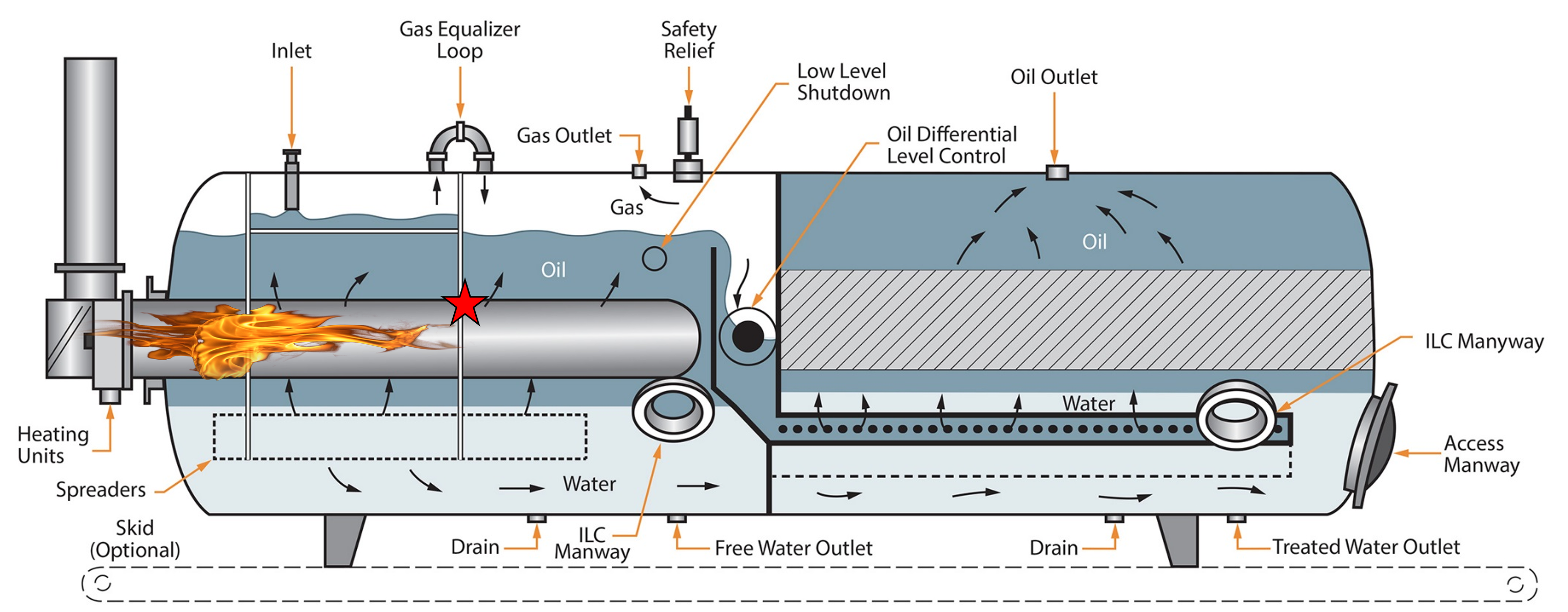

The height of the weir tube in the water leg determines the height of the liquid in the vessel and the oil skims into. A diagram of a tank battery with crude oil lines marked with an O. In the event of pipeline shut-in the gas from the heater treater can be flared. Whether for fuel gas conditioning or regeneration gas heating tank and suction heating air heating jacketed reactor heating and cooling steam superheating seal gas heating or full plant utility heating the processes must be safe effective and reliable while maximizing efficiency. Crude oil transfer is usually achieved by pumping and for this we integrate liquid pumping skids into our packages in partnership with pump suppliers recognised throughout the upstream oil sector. The Horizontal Heater Treater utilizes heat and mechanical separation enhancement devices such as plate packs baffles and electrostatic grids.

The Horizontal Treater is designed to efficiently treat large capacities of crude oil by removing water and emulsion from the wellstream preparing the treated oil.

A typical vertical low pressure oil-gas separator with mechanical controls and the features as previously described is illustrated in Figure 8. It also can reduce crude quality leading to product loss reprocessing and higher operating costs. A heater treater consists of four sections that perform the following functions. Keep it as a reference for. Oil conditioning unit 10B including surge drum 12B can be used if unstabilized crude oil is conditioned from a heater-treater such as heater-treater 11. Whether for fuel gas conditioning or regeneration gas heating tank and suction heating air heating jacketed reactor heating and cooling steam superheating seal gas heating or full plant utility heating the processes must be safe effective and reliable while maximizing efficiency.

Source: oilseparator.co.id

Source: oilseparator.co.id

In order to despatch crude oil between the production wells and treatment installations we supply production manifolds that are normally assembled on self-supporting skid structures. How Does an FWKO Work. Figure 6-11 illustrates a typical design of a horizontal electrostatic treater. Keep it as a reference for. The heat allows for easier separation of the oil and water and also allows solid particles such as sand and corrosive products to settle out.

Source: naturalgasindustryhub.com

Source: naturalgasindustryhub.com

It also can reduce crude quality leading to product loss reprocessing and higher operating costs. The flow path in an electrostatic treater is the same as a horizontal treater. The oil conditioning unit of this disclosure operates downstream of the heater-treater if a heater-treater is used and upstream of stabilized crude storage. Flow enters the top of the treater into a gas separation section. The Horizontal Heater Treater utilizes heat and mechanical separation enhancement devices such as plate packs baffles and electrostatic grids.

In the event of pipeline shut-in the gas from the heater treater can be flared. Crude oil transfer is usually achieved by pumping and for this we integrate liquid pumping skids into our packages in partnership with pump suppliers recognised throughout the upstream oil sector. This view further shows a circuit diagram including means of deenergizing the electric field of the electric treater when the water content of the crude flowing through the electric field exceeds a predetermined level and means of controlling the temperature of the heater-treater so as to increase the temperature thereof when required to remove the additional entrained water from the crude by increasing the temperature of the heater-treater. Keep it as a reference for. Once crude oil has been diverted into a specialized vessel like a heater-treater it will often have to follow a separate path back to where it is held in the stock tanks.

The flow path in an electrostatic treater is the same as a horizontal treater. Flow enters the top of the treater into a gas separation section. The fluids flow through a perforated baffle then a bent lamella separator before entering a settling portion of the tank where gas and water exit via the gas and water outlets and oil flows over an oil weir and exits via the oil outlet downstream of the weir. For optimal safety and minimal risk construction adheres to the latest ASME standards and Exterrans proven pre-engineered design means its in stock and ready for immediate delivery. The oil conditioning unit of this disclosure operates downstream of the heater-treater if a heater-treater is used and upstream of stabilized crude storage.

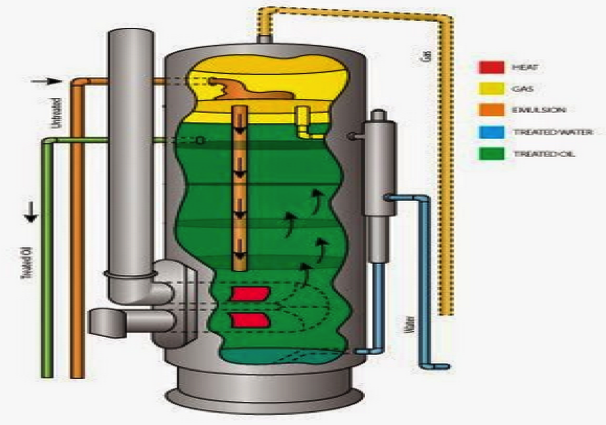

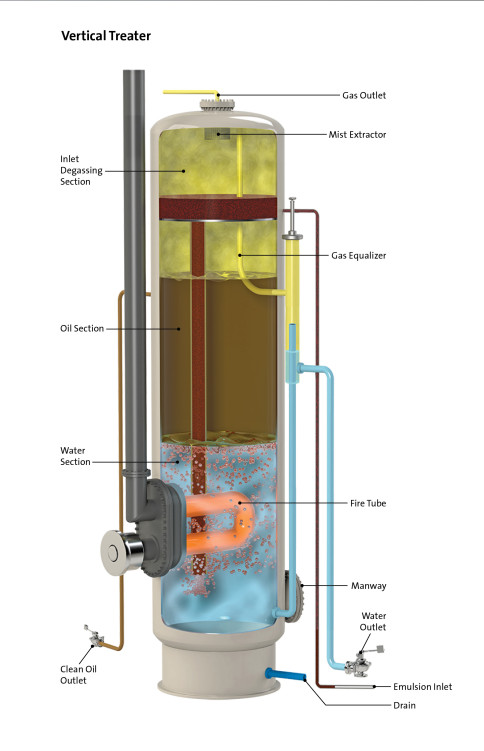

A heater treater consists of four sections that perform the following functions. How Does an FWKO Work. 10Heater Treater removes emulsified liquids and solids from crude and also use heat and pressure drop to flash volatile vapours. The heat allows for easier separation of the oil and water and also allows solid particles such as sand and corrosive products to settle out. Vertical Treater is designed to efficiently treat crude oil by removing water and emulsion from the wellstream so the oil can be further processed or delivered.

Source: oilprocessing.net

Source: oilprocessing.net

The heat allows for easier separation of the oil and water and also allows solid particles such as sand and corrosive products to settle out. Typical crude oil treatment system separation heating dehydration stabilization storage metering pumping Gas to compression processing Gas to compression processing Crudecrude exchanger Crude heater Electrostatic treater heater treater degasser desalter Oil dehydration Gas to compression dehydration Water to water treatment Water to water treatment. What to do with this guide. A diagram of a tank battery with crude oil lines marked with an O. The most commonly used single-well lease treater is the vertical treater as shown in Figure 6-8.

Source: researchgate.net

Source: researchgate.net

Untreated crude enters the degassing section via an inlet located at the top of the vessel and dry associated gases are vented into a gas collection line containing a mist extractor. Refinery heaters Petrochemical heaters Hot oil heaters Regen gas heaters For even more terms and details about fired heater design we recommend the API 560 standard. A heater treater is a pressure vessel that uses heat and residence time to separate clean dry oil from incoming fluids. Untreated crude enters the degassing section via an inlet located at the top of the vessel and dry associated gases are vented into a gas collection line containing a mist extractor. In order to despatch crude oil between the production wells and treatment installations we supply production manifolds that are normally assembled on self-supporting skid structures.

Source: medium.com

Source: medium.com

Crude oil production and processing facilities also rely on a range of indirect steam generators for maximum cost. The Horizontal Heater Treater utilizes heat and mechanical separation enhancement devices such as plate packs baffles and electrostatic grids. The natural gas stream is tied into a pipeline. A typical vertical low pressure oil-gas separator with mechanical controls and the features as previously described is illustrated in Figure 8. Gas and liquids rise to the surface through the well head.

Source: slideplayer.com

Source: slideplayer.com

In order to despatch crude oil between the production wells and treatment installations we supply production manifolds that are normally assembled on self-supporting skid structures. The flow path in an electrostatic treater is the same as a horizontal treater. The heat allows for easier separation of the oil and water and also allows solid particles such as sand and corrosive products to settle out. 11 Demulsifier is a chemical used in the heater treater to separate water from oil. Some treaters use an electrode section.

Source: slideshare.net

Source: slideshare.net

The speed of separation usually depends on a variety of factors. A typical vertical low pressure oil-gas separator with mechanical controls and the features as previously described is illustrated in Figure 8. Water remains at the bottom of the tank and oil completely surrounds a horizontally oriented u-shaped firetube which heats the oil. A diagram of a tank battery with crude oil lines marked with an O. If there is an emulsion it will float between the two.

Source: researchgate.net

Source: researchgate.net

Crude oil transfer is usually achieved by pumping and for this we integrate liquid pumping skids into our packages in partnership with pump suppliers recognised throughout the upstream oil sector. The speed of separation usually depends on a variety of factors. Keep it as a reference for. Crude oil from the heater treater is sent to a VRT. 11 Demulsifier is a chemical used in the heater treater to separate water from oil.

Source: researchgate.net

Source: researchgate.net

The vertical separator has the. Emersons heater treater solutions provide greater insight into treater health and process integrity resulting in fewer production allocation errors more effective maintenance and reduction in HSE risks. The Horizontal Treater is designed to efficiently treat large capacities of crude oil by removing water and emulsion from the wellstream preparing the treated oil. Untreated crude enters the degassing section via an inlet located at the top of the vessel and dry associated gases are vented into a gas collection line containing a mist extractor. For optimal safety and minimal risk construction adheres to the latest ASME standards and Exterrans proven pre-engineered design means its in stock and ready for immediate delivery.

Source: slidetodoc.com

Source: slidetodoc.com

The incoming stream of untreated oil enters the heater treater below the level of the separated oil. Whether for fuel gas conditioning or regeneration gas heating tank and suction heating air heating jacketed reactor heating and cooling steam superheating seal gas heating or full plant utility heating the processes must be safe effective and reliable while maximizing efficiency. What to do with this guide. The flow path in an electrostatic treater is the same as a horizontal treater. In order to despatch crude oil between the production wells and treatment installations we supply production manifolds that are normally assembled on self-supporting skid structures.

Source: researchgate.net

Source: researchgate.net

It usually is located immediately downstream of the Free Water Knockout during the oil dehydration process. The speed of separation usually depends on a variety of factors. If there is an emulsion it will float between the two. Crude oil from the heater treater is sent to a VRT. 11 Demulsifier is a chemical used in the heater treater to separate water from oil.

Source: jmcampbell.com

Source: jmcampbell.com

The most commonly used single-well lease treater is the vertical treater as shown in Figure 6-8. If there is an emulsion it will float between the two. It also can reduce crude quality leading to product loss reprocessing and higher operating costs. 10Heater Treater removes emulsified liquids and solids from crude and also use heat and pressure drop to flash volatile vapours. It usually is located immediately downstream of the Free Water Knockout during the oil dehydration process.

Source: slidetodoc.com

Source: slidetodoc.com

We have also created several other guides all of which are available on the Resources page of our website. The height of the weir tube in the water leg determines the height of the liquid in the vessel and the oil skims into. The Horizontal Treater is designed to efficiently treat large capacities of crude oil by removing water and emulsion from the wellstream preparing the treated oil. The only difference is that an AC andor DC electrostatic field is used to promote coalescence of the water droplets. For optimal safety and minimal risk construction adheres to the latest ASME standards and Exterrans proven pre-engineered design means its in stock and ready for immediate delivery.

Source: integratedlearning.net

Source: integratedlearning.net

A Heater Treater is used in the oil and gas production process for the purpose of removing contaminants - typically being liquid hydrocarbons water and produced water - from natural gas. Gas and liquids rise to the surface through the well head. We have also created several other guides all of which are available on the Resources page of our website. Crude oil production and processing facilities also rely on a range of indirect steam generators for maximum cost. The gasliquid mixture enters the heater treater to separate the natural gas crude oil and produced water.

Source: greasebook.com

Source: greasebook.com

Gas and liquids rise to the surface through the well head. Whether for fuel gas conditioning or regeneration gas heating tank and suction heating air heating jacketed reactor heating and cooling steam superheating seal gas heating or full plant utility heating the processes must be safe effective and reliable while maximizing efficiency. For optimal safety and minimal risk construction adheres to the latest ASME standards and Exterrans proven pre-engineered design means its in stock and ready for immediate delivery. How a Heater Treater Works. The fluids flow through a perforated baffle then a bent lamella separator before entering a settling portion of the tank where gas and water exit via the gas and water outlets and oil flows over an oil weir and exits via the oil outlet downstream of the weir.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site helpful, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title crude oil heater treater diagram by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.